HIGH-ORDER IMMERSED-BOUNDARY METHODS IN SOLID MECHANICS FOR STRUCTURES GENERATED BY ADDITIVE PROCESSES

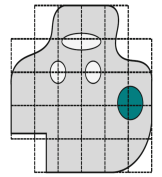

Laufzeit: 01.11.2014 – 31.08.2021 Projektleiter: Univ.-Prof.Dr. Andreas Schröder Projektmitarbeiter: Paolo Di Stolfo Kooperationspartner: Prof. Dr. Alexander Düster, TU Hamburg-Harburg (TUHH), Prof. Dr. Ernst Rank, TU München (TUM) Fördergeber: Deutsche Forschungsgemeinschaft (DFG) In the past few years additive manufacturing (also named 3D-printing) has evolved to one of the most promising techniques for creating solid structures of virtually any shape on the basis of digital models. 3D- printing is achieved by successively generating layers of material of different shapes, often also of varying material properties. Applications for additive manufacturing range across virtually all fields in mechanical engineering, from non load bearing architectural models for mere visualization of designs to parts under severe loads as in the lightweight components for the automotive or aerospace industry. Additive manufacturing poses many questions to a numerical simulation of the process itself and the products obtained, which can only be partially or, in many cases only very inaccurately be answered by today’s simulation technologies for solid mechanics. In the project it is intended to further develop the Finite Cell Method (FCM), a high-order immersed-boundary approach to tackle a significant part of these problems. An in-depth mathematical analysis of the FCM will shed more light on the structure of this newly developed method and help in improving the concepts especially with respect to error controlled adaptivity. The project is a common research project of TU Hamburg-Harburg (TUHH), TU München (TUM) and Paris Lodron-Universität Salzburg (PLUS). Projektseite